Ever wondered, what is Biogas Made Up Of? Biogas is a mixture of gases produced as a result of anaerobic decomposition. This process is one step further than simply using organic waste to create manure. Here, we take the already processed manure and other un-or-under processed organic waste. And break it down with the help of methanogenic bacteria.

A key part of this process is ensuring that his breakdown happens in the absence of oxygen. Which is what puts the ‘an’ in anaerobic. This can happen naturally in landfills, where organic waste is often trapped in large piles. Which are then compressed with inorganic plastic. To reduce the presence of oxygen and cause this process to occur.

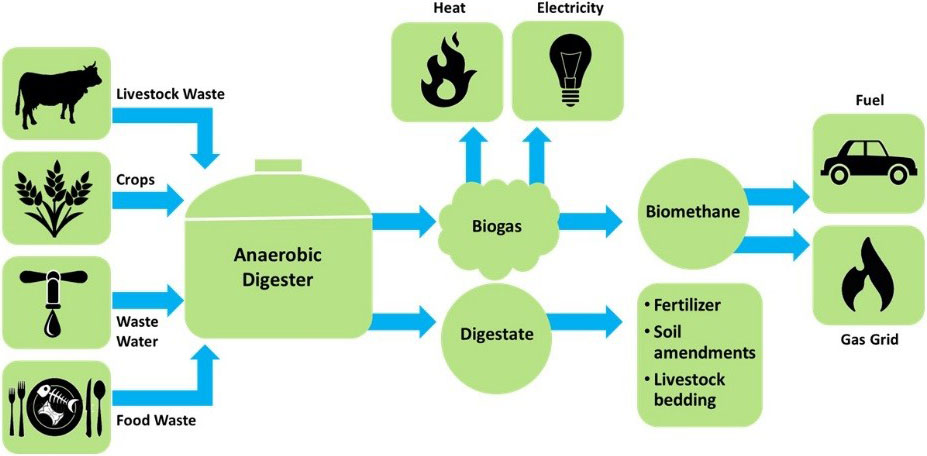

Anaerobic digestion process (Graphic by Sara Tanigawa, EESI).

Or intentionally, in man-made biogas plants. Which have special air-tight chambers that can hold thousands of kgs of organic waste. Such man-made plants use raw materials such as agricultural waste, sewage, municipal waste, green waste, manure, plant material, and other food waste.

The gases that are initially released as a result of this process can then be made into usable biogas. Biogas is a mixture of gases like methane, carbon dioxide, hydrogen, and other contaminants. The composition can vary depending upon the substrate composition, as well as the reactor conditions. This includes temperature, pH, and even substrate concentration.

On average, the different composition is generally like this:

As we mentioned above, this process also produces a few containments. Which can be pretty harmful to the environment. These include a few major ones like:

Sulfur compounds by nature are toxic and foul-smelling. In biogas, they can be found in the form of Hydrogen sulfide (H2S). This compound is present in the highest quantity. Even though there are also other compounds like thiols present in the mix.

These compounds must be removed from the biogas and treated properly. As they can be corrosive to the delivery pipes and other materials they are exposed to. Even if that isn’t enough of a deterrent against these compounds. Burning them produces further toxic materials. Like sulfur dioxide (SO2) and sulfuric acid (H2SO4), which are proven environmentally hazardous compounds.

Even though biogas production already produces some amount of nitrogen. It is not the ultimate thing to worry about. As further breakdown of nitrogen can also produce quantities of Ammonia (NH3). This generally happens when bacteria break down amino acids in food proteins.

Once again, we must separate this contaminant from biogas before use. As burning it can result in the formation of nitrous oxide. Nitrous oxide (N2O) is a highly polluting greenhouse gas. Which is 320 times more aggressive than carbon dioxide.

Even though soaps and detergents aren’t technically organic compounds. They are often decomposed alongside organic materials. Due to their common presence in our wastewater. This process can release compounds known as siloxanes.

If we don’t treat them out of biogas before burning them. It can cause the release of silicon. Which can combine with free oxygen or other elements. To form various deposits of silica (SiO2) or silicates (SixOy). Which can contain materials like calcium, sulfur, zinc, phosphorus, etc. These white mineral deposits can corrode or even block the pipes. And require special chemical or mechanical treatments to remove.

Due to the presence of so many wanted and unwanted materials in biogas. It requires proper treatment before it can be used as fuel. The most basic form of treatment is the removal of carbon dioxide. Which is not usable as a fuel source.

Once the CO2 is removed, biogas can be easily compressed. The same we compress natural gas to CNG and use it to power motor vehicles. Biogas can be further cleaned and upgraded to bio-methane. Which includes processes like water scrubbing and membrane separation. This alone accounts for almost 60% of global biomethane production.

The great thing about these processes is that they are a truly renewable resource of energy. As the production-and-use cycle is continuous and generates no net carbon dioxide. It also deals with the issue of organic waste. That is produced by both the agriculture and dairy industries.

If we could simply tap into the waste produced by the millions of cattle in our country. We could easily produce enough electricity to power millions of homes across the nation. For reference, just one cow can produce enough manure in one day to generate 3 kilowatt-hours of electricity. Furthermore, by taking this waste out of the system, we could reduce global warming gases by an equally significant amount.

Unfortunately, that is easier said than done. As the development of biogas has been uneven across the world. In fact, Europe, China, and the United States account for 90% of global production. With countries like Thailand, India, Argentina, and Brazil making up the rest of the production capacity. On a whole, we produce barely 3.5 Mtoe of biomethane with our global biogas capacity.

What is Biogas Plant and how does it work?

It will require serious investment by the government, as well as private companies to get this number up. To such a significant number. Where we can actually count biogas as one of the major sources of renewable energy.

India can play a big role in this process. As we already have millions of cattle that produce lots of waste. Which can add up to over 1000 MTA. As well as a growing population of over a billion. Which contributes significantly to the global waste produced each year. Almost up to 700 MTA just through our agricultural practices alone.

By diverting these organic wastes towards energy production. We can greatly reduce our dependency on foreign oil and gas. And make India a truly self-sustaining nation. The government is already making moves to encourage this process. By giving out a 20% subsidy on the installation of biogas plants.

Still, so far, we have only managed to install 163 plants. That offers a combined energy savings of over 787 lakh rupees each year. It is our hope that as more and more people start to consider the value of biogas. We will see these numbers going up significantly.

Leave a Reply