The seafood processing industry is one of the largest in the world, and it also accounts for a large percentage of the waste produced by this industry. Fish and crustaceans are often used in the production of fish and other seafood products. Seafood is a very important part of the diet in many countries around the world, and it is expected to be widely consumed in the future.

The seafood industry takes raw materials from seawater, which are then processed by humans or machines to give them their final shape and size. At this stage, water from seawater enters the fish’s gut, where it flows through its digestive system and leaves feces (waste).

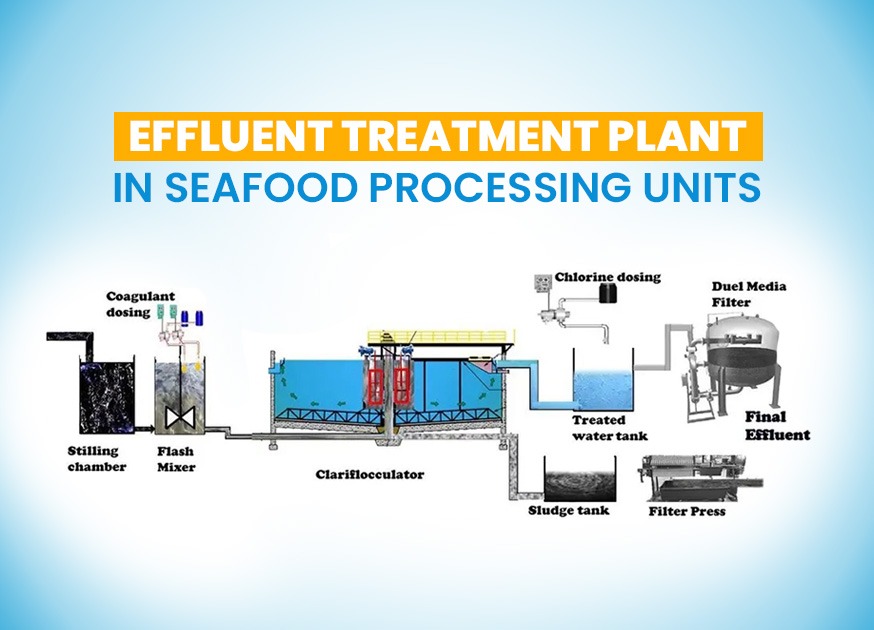

After this process, wastewater containing high levels of nutrients must be removed from the plant before it can be returned to seawater through an effluent pipe or pond. This wastewater can be treated using various technologies such as UV light treatment or reverse osmosis (RO) filtration systems or using a combination of physical and biological methods to reduce nutrients, pathogens, and odors.

Wastewater Composition

Wastewater from the seafood processing industry is highly contaminated with a wide range of organic and inorganic compounds. The water is often subjected to a variety of physical, chemical, and biological processes that lead to the formation of high levels of organics and minerals within the wastewater.

These contaminants can include heavy metals such as copper, zinc, mercury, chromium, and nickel; volatile organic compounds (VOCs) such as phenol; pesticides; herbicides; non-ionic surfactants; polycyclic aromatic hydrocarbons (PAHs); polychlorinated biphenyls (PCBs); dioxins/furans; dyes; UV disinfection Byproducts (UVCBs); heavy metals; heterocyclic amines (HCAs), including 2-amino-1-methyl-6-phenylimidazo[4,5-b]pyridine (PhIP); endocrine disrupting chemicals (EDCs); pharmaceuticals; antimicrobial agents such as Triclosan; antimicrobial peptides such as Fucus.

The flow rates depend heavily on the plant’s operations. The waste can be divided into two types:

1. High salinity wastewater – Such wastes are the byproducts by the use of seawater in part of the method.

2. Low salinity wastewater – They result from the use of freshwater that has no salinity produced as a by-product.

Cleaning Wastewater – This is generated by washing machines that directly come in touch with the product. For example – Pressing and bringing, equipment breakdown, product leakage, even operational errors, and CIP effluents. Highly contaminated in nature, these wastes are produced in abundance, requiring additional treatment.

Sanitary Wastewater – This type of wastewater can be found in the drainage systems like – shower rooms, restrooms, and other public areas. Sanitary wastewater is always piped straight to sewage treatment plants. Nevertheless, it is a good source of nitrogen for imbalanced waste byproducts prior to additional aerobic treatments.

Wastewater treatment system filters

One of the most common types of wastewater treatment systems is an activated carbon filter. This type of filter uses a combination of carbon and other materials to remove pollutants from water, making it suitable for fish processing facilities that deal with high levels of solids and particulates in their wastewater streams. The activated carbon filter can also be used to treat industrial effluent or surface water, which makes it ideal for use in fish processing facilities that deal with polluted water sources or industrial waste streams.

Another type of wastewater treatment system is granular media filters. These filters typically use sand, gravel, or another type of granular material to remove contaminants from the wastewater stream before it enters your fish processing facility’s treatment plant. Another benefit to using this type of filter is that it can be easily replaced after each season if needed (or if there’s something wrong with it).

Seafood water processing system

Seafood processing wastewater is often discharged into the ocean and can contain large amounts of protein and oil. This treatment is a process that removes nutrients and harmful substances from seafood processing wastewater. The primary treatment processes are screening, sedimentation, flow equalization, and dissolved air flotation.

(i) Equalization

For a more homogenous and consistent flow to the flotation machine, the industrial effluent needs to be properly equalized. This process lowers the hydraulic surging which can negatively impact the performance of the system. To let the EQ tanks operate for a specific time, it is advisable to give a specific size to these tanks.

(ii) Screening

One of the most straightforward, screening provides self-cleaning mechanisms to treat wastewater. Here the tangential screens do not get clogged easily and the washed trapped solids are collected in the upper section of the drum. These solids are pushed to the upper section by a strong stream of water and the wastewater flows outside the drum. A very cost-effective method, this process can eliminate around 80% of the solids.

(iii) Coagulation and Flocculation

Coagulation – When you insert oppositely charges ions/molecules that destabilize the colloidal suspensions by neutralizing surface charge.

Flocculation – A process of producing huge stable flocs that either float or sediment. Flocculants are substances that link smaller coagulation flocs together.

The three methods of wastewater treatment – Coagulation, Flocculation, and Floatation are considered to be the most effective for removing oily substances like – grease and fats. They are quite vital in eliminating particles and colloidal components as well.

In the treatment of seafood-processing wastewater, one should be aware of the important constituents in the waste stream. This wastewater contains considerable amounts of insoluble suspended matter, which can be removed from the waste stream by chemical and physical means.

The wastewater is contaminated with microbes and other environmentally harmful substances like COD, FOG, BOD, and TSS. There is a huge demand and requirement to treat such substances before they hit the nearby water bodies as they have impacted our environment adversely for a long time period and will continue to do so if the effluents are not treated with the correct methods.

About Ace Dynamics

An environmentally charged organization, Ace Dynamics enthusiastically innovates eco-friendly water harvesting and management technology. Maneuvering its vision to a sustainable future under the Brand name ‘Blue Sea’, the company provides, designing, manufactures, and supplies solutions for wastewater treatments, reverse osmosis systems, water treatment plants, Ozone generators, Effluent treatment plants, and swimming pool filtration methods. The experts here are capable of taking annual maintenance contracts of the above-said categories as well.

How Hydro energy is maneuvering a green future?

Leave a Reply